Different drum sets

Whether you own an electronic or an acoustic drum kit, contact noise is a common problem with both types. The pedals of a drum kit, the one from the bass drum(s) and the hi-hat, cause the sound problem. Although the electronic drum kit is (relatively) quiet in terms of air noise, the neighbours can still experience nuisance through contact noise. The sound problems of an acoustic drum kit consist of both contact and airborne noise.

This tips page mainly deals with insulating contact noise. Next to two different types of drum sets, there are also two different solutions. We discuss a ready-made and a DIY-solution. The biggest difference between the two is that the DIY-method can be individually tailored and adjusted by yourself.

The solutions

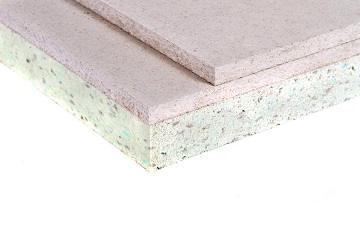

Ready-made floating floor system, Akoestifloor Icotop 40

The easiest solution is to create a 'floating' platform by means of Akoestifloor panels. Akoestifloor Icotop is suitable for every floor type and under every drum set. You can apply the product in two ways.

The first way is to insulate part of the floor, that is, only where the drum kit is located. This application forms a kind of platform that is spacious enough for the drum set and possibly the stool. The second (better) way is to insulate the entire floor with Akoestifloor. This may require more time and money, but certainly in case of an acoustic drum set, this method is way more efficient, since both sound problems, contact and air sound, are being addressed.

Mounting Akoestifloor

Applying Akoestifloor panels is easy. Equip the wall(s) of the room with Agglomer Strips. You apply them in the same way as skirting boards. The Akoestifloor panels are installed upon them, resulting in a seperation between the panels and the walls. The Akoestifloor panels have an overlapping connection lip, which is equipped with Akoestifix Seam Glue. After 10 minutes, the glue has dried a bit and one panel is glued on top of the other. For extra strength, the panels can be screwed on top of each other with the F2 screws (a screw every 10 cm). Then add the screed, such as laminate, parquet or carpet.

For a platform of 2600 x 1800 mm you need six Akoestifloor Icotop 40 panels, one can of Akoestifix Seam Glue and a box of F2 Screws. You can order all products individually, so it's up to you how big the plateau will be. For larger purchases, for example to insulate an entire floor, a discount is calculated according to the discount scale.

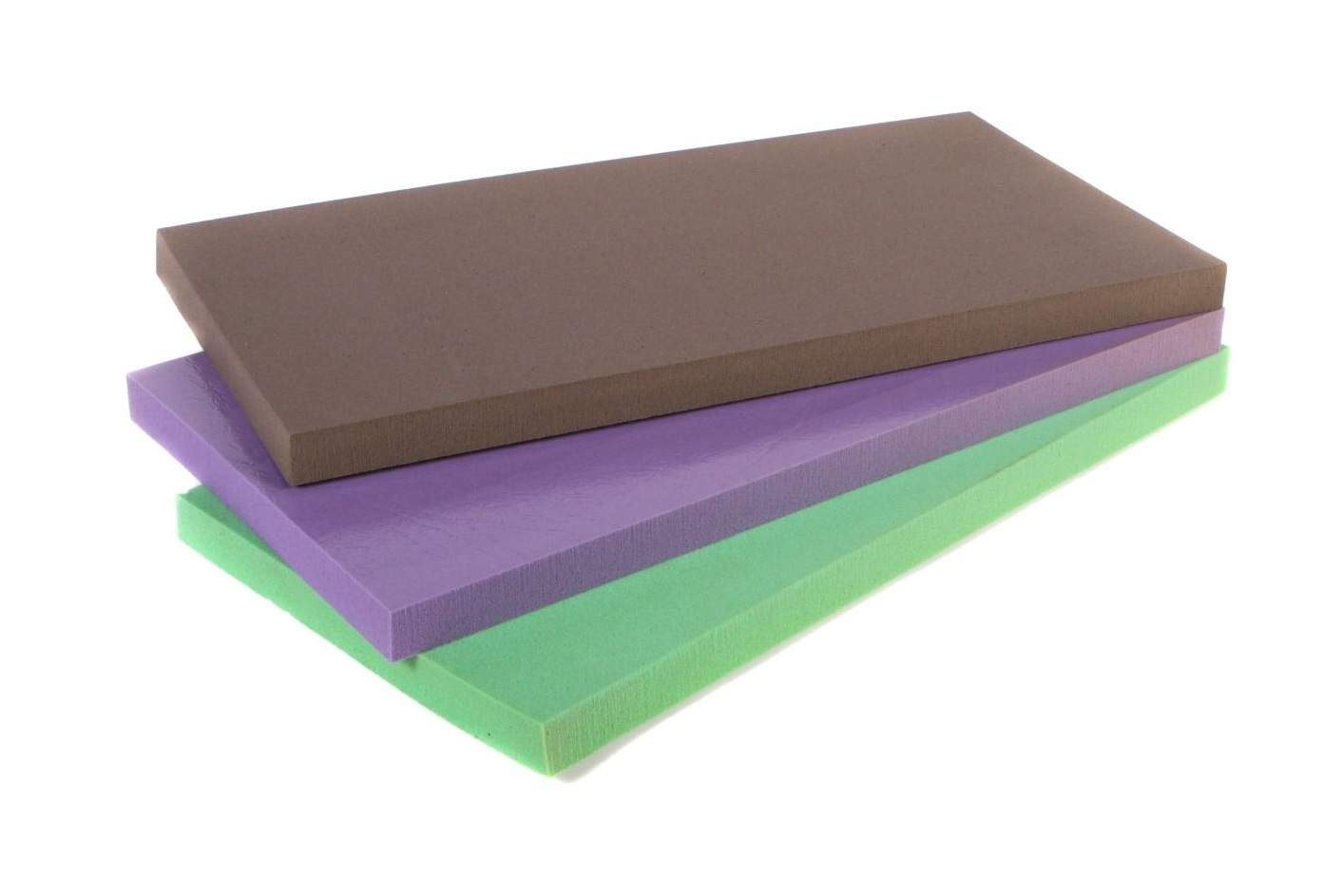

Regufoam Vibration insulation

This is the DIY-method that uses Regufoam vibration insulation. The solution consists of a homemade plateau, possibly made of thick MDF, placed on Regufoam. The advantage of this method is that you can give the plateau the desired shape and size, and that vibration insulation can individually be adjusted by reducing or adding the amount of Regufoam. This can be useful because every drum set differs in weight and size, which is also true for the drummer in question.

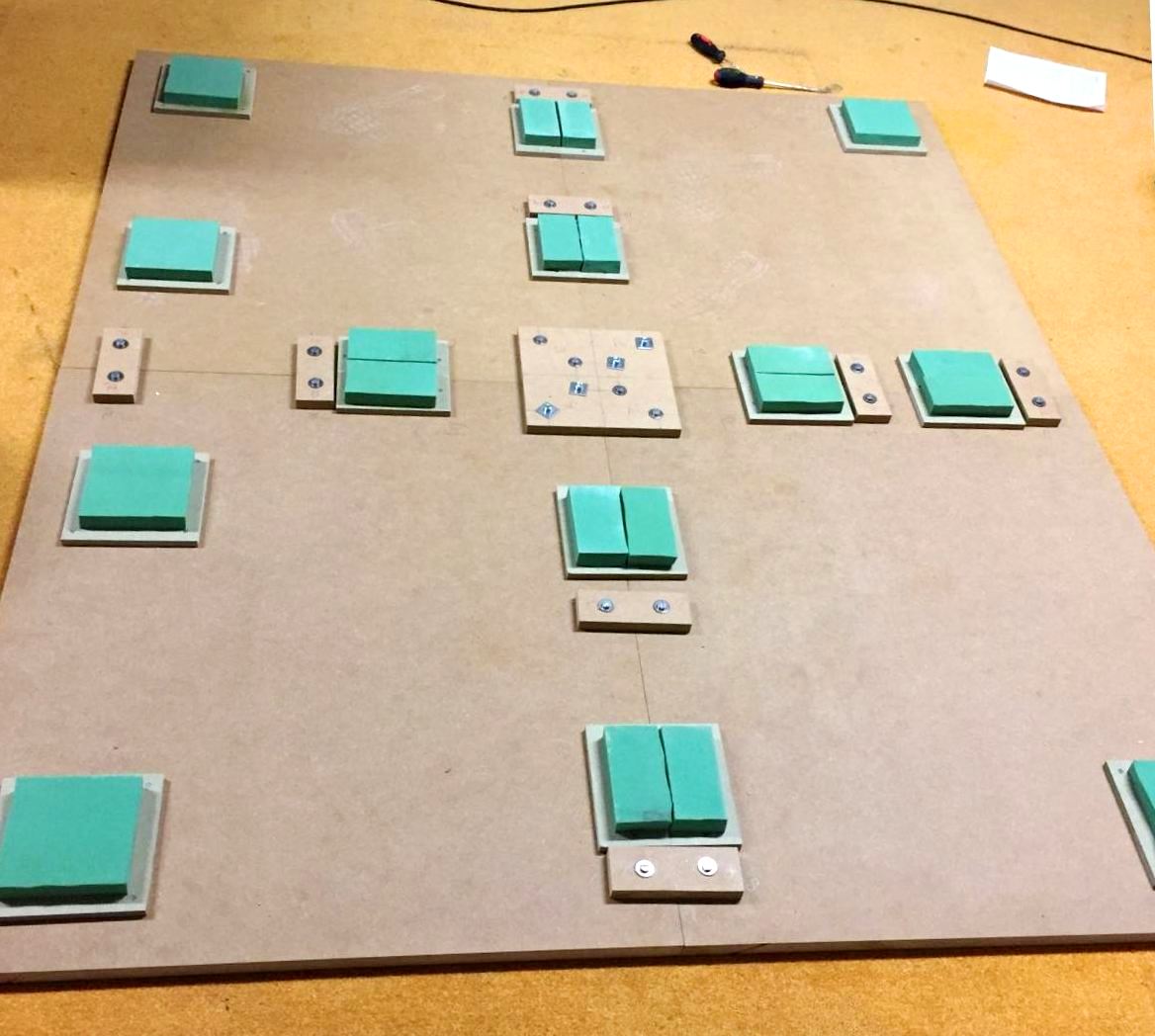

The customer below has carried out this method in the following way. Our customer has cut Regufoam mats (type D150 with a thickness of 25 mm) in blocks and glued them together, with Zettex Contact glue.

He then strategically distributed the blocks under a heavy MDF panel with a thickness of 18 mm. When the blocks are attached, they have a size of about 125 x 125 mm and a thickness of 50 mm. After testing if the Regufoam blocks are placed correctly, they can be glued.

The amount and placement of the blocks is correct if the plateau is stable. The platform should indent a little bit when you stand on it. In general, three mats of Regufoam D150 (M0715) are sufficient. Following the example you should cut out 16 blocks. Our customer finished the plateau with a black carpet. Read the comment and have a look at the photos he sent us:

"Yes, it works, and the thumping sound has been significantly reduced. What you see is the bottom of the plate which I turned around. It is very stable, and I am very happy with it. Thanks for the extra pieces of foam and the good service!”

Extra tips

We recommend you use the heaviest sheet material possible for your platform. This reduces the chance of airborne noise from underneath the plateau. If you still notice a hollow sound, you can equip the empty space under the plateau with Akotherm D40. In the example above, this was not necessary because of the carpet as a floor covering in the attic. Using carpet as finishing material reduces sound reflections, thereby improving room acoustics. Also, in order to get rid of reverberation and to improve room acoustics we have a tips page called “Do you suffer from reverberation?”.

Drum sound studio

If a floating floor is not a sufficient solution because you also produce a lot of airborne noise in addition to contact noise, then consider a sound studio. In our range you will find the Studio bricks sound studios. This studio can be customised in various sizes, up to no less than 9 x 5 meters! You are welcome in our showroom to view the studios!

Questions?

Do you have any questions about this topic? Please feel free to contact us.

Sound Absorption

Sound Absorption  Sound Insulation

Sound Insulation  Vibration Isolation

Vibration Isolation  Silent Ventilation

Silent Ventilation  Accessories

Accessories  Thermal & Acoustic Insulation

Thermal & Acoustic Insulation