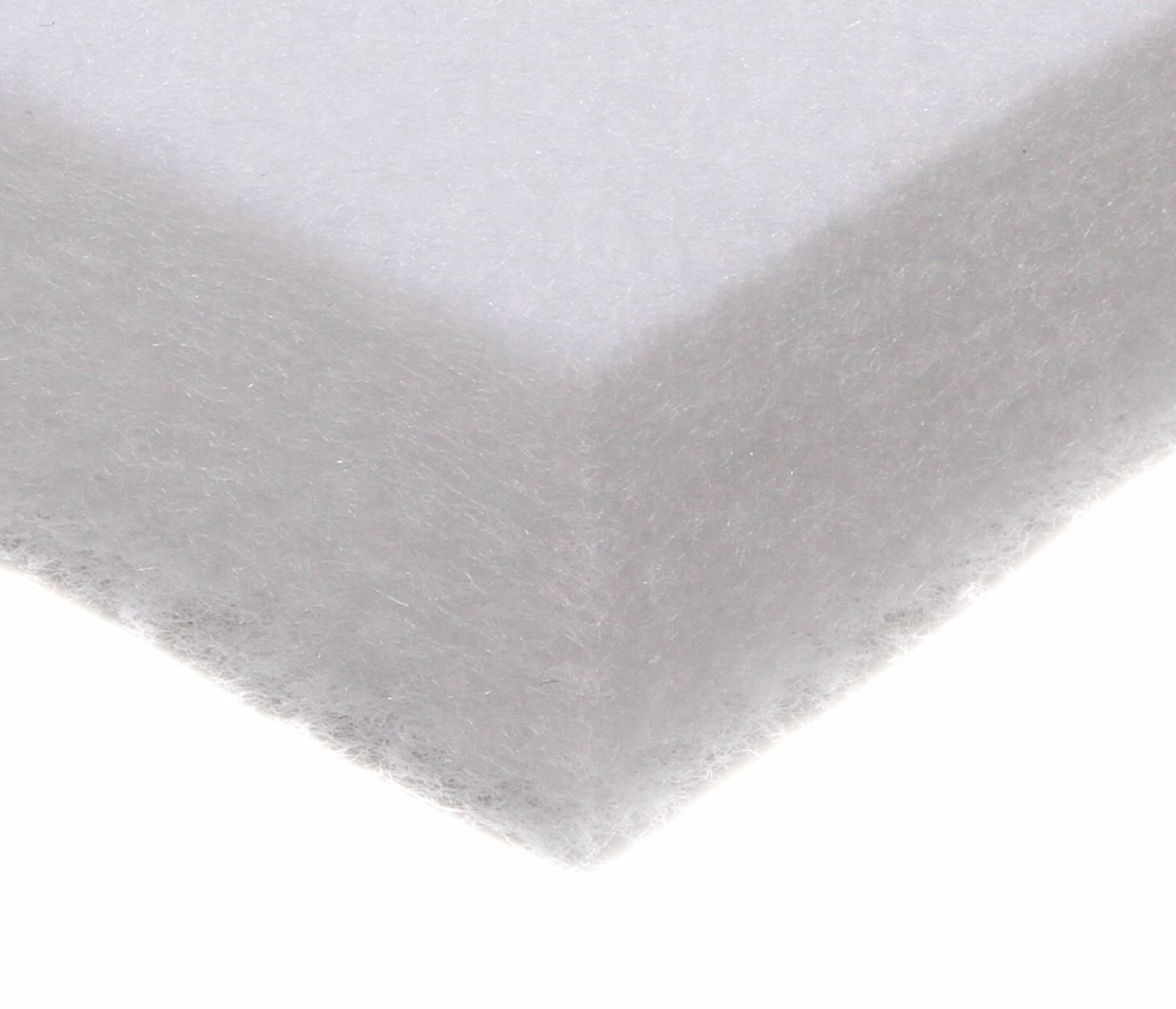

At the beginning of 2002, Merford Acoustic Materials was the first company to introduce a refined form of polyester wool to the acoustics industry. This product was launched on the market as an alternative to traditional mineral wool such as glass and stone wool. Because this variant of polyester wool has excellent thermal insulation and absorption values, the name Akotherm was quite obvious. The first type of Akotherm was available at a density of 20 kilograms per cubic metre, a plate size of 1200 x 600 mm, and in four thicknesses.

Nowadays, we offer the Akotherm product in numerous variants and compositions. The product has evolved into one of the most applicable products in the range from the Acoustics Shop. This range is currently so big that the types of applications are countless, of which the most common ones are acoustic (panel) filling, cavity filling, insulation and absorption for machines and appliances, such as central heating and heat recovery installations. Akotherm is also used as wall and ceiling cladding for improving room acoustics as well as for thermal insulation in, for example, yachts, ships, and vehicles.

Product description

Akotherm is manufactured from polyester fibres that come from newly produced material or from recycled plastic such as PET bottles. The exact consistency depends on the application and the product requirements. Also, during the production process, residual material (for example from cutting) are added back into the process, making Akotherm 100% recyclable! Unlike other polyester wool products, Akotherm consists of long and bonded fibres, preventing the product from tearing. This process results in a much stronger product than most other polyester wool products. Because Akotherm does not disintegrate, it has a particularly long service life.

Akotherm processing

Because Akotherm does not cause an allergic skin reaction, the product is comfortable to work with and does not need to be shielded by a fleece or a textile. Akotherm can be customised to your needs on a project basis in our production facility. Think of water cut measuring, which allows for complex shapes and cutouts or simple strips in a certain size. You can also perfectly cut Akotherm to size by yourself. For this purpose, in addition to our ceramic knife, you can also consider using an electric foam saw.

Standard Akotherm variants

Merford Acoustic Materials has a large amount of Akotherm variants in stock. The types that are most commonly used are Akotherm Basic, Akotherm D40 and Akotherm GG. In addition to these stock variants, Akotherm can also be custom-made. Consider high densities up to more than 200 kilograms per cubic metre in sheet form for example, or Akotherm on rolls up to a maximum of 20 running metres. Akotherm can be supplied with or without a self-adhesive layer. Below we discuss the specifications of various products we have in stock.

- Akotherm Basic

This Akotherm variant has a density of 20 kilograms per cubic metre and is provided with a final top layer. By post-processing the product at one side with needles, a compacted layer of 2 to 3 mm thick is obtained. This layer provides more strength and diminishes the chance of damage. This layer is still acoustically open, but does not protect against oil and moisture penetration. Akotherm Basic is often used as a semi-finished product in the machine and appliance industry. Furthermore, it can be used as thermal cavity wall insulation and as a filling for products such as acoustic visuals, panels and damper filling.

- Akotherm D40

This is a product that is comparable to the Basic variant, the biggest difference being a doubling of the density to 40 kilograms per cubic metre (D40). Since the production process is slightly different from the one from the Akotherm Basic, the product obtains a slightly visible waffle structure on one side. The increased density results in a slightly higher absorption value, more stiffness as well as more resistance, preventing the Akotherm D40 from slumping. These plates can be used on visible spots, for example in order to improve room acoustics in the form of a wall or ceiling solution. Akotherm D40 is also used as a filling in splitter attenuators.

- Akotherm GG

The Akotherm GG is the most beautiful polyester wool product on the market. A special post-processing on both sides of the plate, GG, results in a top layer with the smoothness and tightness of fleece, without nearly costing as much as fleece! Thanks to this special post-processing, Akotherm GG is ideal to cover a wall or ceiling without the need for a finishing layer. The price, quality, and absorption ratio is particularly favourable. As a result you can cover a relatively large number of square metres at a competitive price!

- Akotherm Facet

A faceted Akotherm D40 variant. The angled faceted edge gives this Akotherm plate just a little more aesthetic value for applications in various rooms for reducing reverberation. The price-quality ratio of this product is also remarkable.

Additional technical specifications

Absorption values

- D20/50 mm: NRC = 0,70; αw = 0,75 (absorption class C).

- D40/50 mm: NRC = 0,80; αw = 0,85 (absorption class B).

- D20/100 mm: NRC = 1,00; αw = 1,05 (absorption class A).

Fire classification

EN 13501-1: 2002 fire class B, smoke number s2, drip number d0. Report no. 2006-Efectis-R0690. Smoke classes s1 and s2, does not apply to all types and thicknesses.

Questions or product samples?

Do you have any questions about this product, or would you like to receive a product sample before ordering? Please contact us. Order information can be found on the product page.

Sound Absorption

Sound Absorption  Sound Insulation

Sound Insulation  Vibration Isolation

Vibration Isolation  Silent Ventilation

Silent Ventilation  Accessories

Accessories  Thermal & Acoustic Insulation

Thermal & Acoustic Insulation